A. SCOPE

This specification applies magnetic buzzer, FMB12A12

B. SPECIFICATION

| No. | Item | Unit | Specification | Condition |

1 | Oscillation Frequency | KHz | 2.3 ± 0.3 | |

2 | Operating Voltage | VDC | 8~ 16 | |

3 | Rated Voltage | VDC | 12 | |

4 | Current Consumption | mA | MAX. 30 | at Rated Voltage |

5 | Sound Pressure Level | dB | MIN. 87 | at 10cm at Rated Voltage |

6 | Response time | mS | Max 50mS | Lowest operation voltage |

7 | Operating Temperature | ℃ | -20 ~ +70 | |

8 | Storage Temperature | ℃ | -30 ~ +80 | |

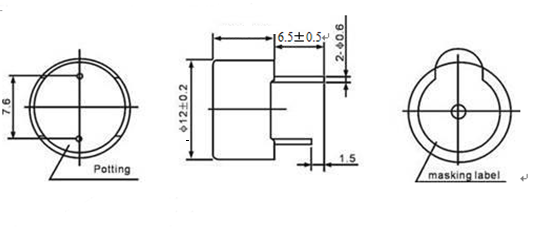

9 | Dimension | mm | Φ12 x H9.5 | See appearance drawing |

10 | Weight (MAX) | gram | 2.0 | |

11 | Housing Material | PPO( Black ) | ||

12 | Leading Pin | Tin Plated Brass(Sn) | See appearance drawing | |

13 | Environmental | RoHS |

C. APPEARANCE DRAWING

Tol : ± 0.5 Unit: mm

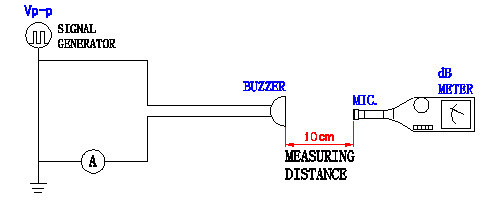

D.TESTING METHOD

Standard Measurement conditions

Temperature:25±2℃ Humidity:45-65%

Acoustic Characteristics:

The oscillation frequency, current consumption and sound pressure are measured by the measuring instruments shown below

In the measuring test, buzzer is placed as follows:

E. VOLTAGE / CURRENT / SOUND PRESSURE CHARACTERISTICS

F. RELIABILITY TEST

NO. | ITEM | TEST CONDITION AND REQUIREMENT |

1 | High Temperature | After being placed in a chamber with 80 |

2 | Low Temperature | After being Placed in a chamber with -30 |

3 | Humidity Test | After being Placed in a chamber with 90-95% R.H. at 40 |

4 | Temperature Cycle | The part shall be subjected to 5 cycles. One cycle shall be consist of: |

5 | Drop Test | Drop on a hard wood board of 4cm thick, any directions ,6 times, at the height of 75cm . |

6 | Vibration Test | After being applied vibration of amplitude of 1.5mm with 10 to 55 Hz band of vibration frequency to each of 3 perpendicular directions for 2 hours . |

7 | Solderability | Lead terminals are immersed in rosin for 5 seconds and then immersed in solder bath of +300 |

8 | Terminal Strength | The force of 9.8N(1.0kg) is applied to each terminal in axial direction for 10 seconds. |

TEST CONDITION.

Standard Test Condition : a) Temperature : +5 ~ +35℃ b) Humidity : 45-85% c) Pressure : 860-1060mbar

Judgment Test Condition : a) Temperature : +25 ± 2℃ b) Humidity : 60-70% c) Pressure : 860-1060mbar

G. PACKING STANDARD

聯(lián)系人:吳經(jīng)理

手機(jī):15722819198

電話:

傳真:

郵箱: